Module SPlicing

Modular Splicing

THE PROBLEM

Wide variations in the network mean installation and maintenance projects often turn out to be complicated and time-consuming. For example, the high variety of cables required for diverse projects curtails efficiency – technicians are delayed as they seek out the optimum high density solution installation. Challenging deployment locations within the network mean that, in advance of project roll-out, project managers need to make provisions for the use of a lengthy checklist of all relevant tools and accessories.

THE SOLUTION

DEXsplice modular splicing connectors respond to the necessity for FAST, ERRORFREE INSTALLATION. With extensive manufacturing and R&D experience, DexGreen is perfectly placed to help simplify the installation and maintenance process and support the carrier with project roll-out. Furthermore, the solutions meet stringent Telecordia requirements and undergo ongoing validation testing, therefore this gives carriers peace of mind of connector durability in the field. The Solution As the result of a comprehensive R&D programme coupled with a rigorous in-house testing process, DEXsplice connectors offer ‘solder-equivalent’ connections that deliver low contact resistance.

SUPERIOR RELIABILITY

Superior material selection and excellent manufacturing standards, ensure long term reliability of the joints in harsh environmental conditions. Pre-filled modules for protection from humidity and condensation. Spliced connectors, when applied with Sealant Box, offer excellent moisture and water resistance

VERSATILITY

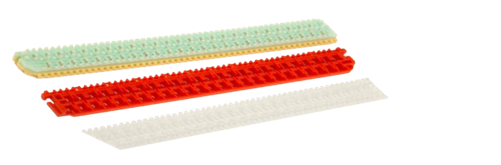

For economical and cost-effective cable splicing solutions DEXsplice™ TC 018 series Modular connectors are available in different models suited for a variety of applications. Full range of products for straight, tap and plugging applications

Splicing of cables are simplified by the use of Splicing Rigs. Simple set-up, systematic and accurate splicing procedure considerably reduces time and effort, resulting in significant savings.

efficiency

Built-in cut-off blades trim excess wire while crimping. Trimming of the conductors is not required. Insulation Displacement Connection (IDC) provides solder-equivalent joint - no need for stripping of the insulation. Single crimp connects multiple pairs of conductors.

Cable Management

Cable management is made easy and accurate - splicing of cables are simplified by the use of Splicing Rigs.

SET UP

A simple set-up allows for a systematic and accurate splicing procedure. This approach reduces time and effort, resulting in considerable savings.

Insulation Displacement Contact

The connector module is equipped with contacts of Insulation Displacement Connection (IDC) technology. Made of superior grade Phosphor bronze material, with tin over copper plating, the contact strips the insulation and provides a cold solder equivalent joint, delivering very low electrical resistance. Our pluggable module allows for the rearrangement or transfer of working lines, without interruption of service.

The compact construction of the connector minimises the splice bundle diameter and reduces the cost of splice closures, thereby maximizing your benefits.

The insulating material of the cover body and base are made of Polycarbonate, a high grade, durable engineering plastic. The materials used in the connector system are compatible with most commonly used materials in the telecommunications network.

Testing of conductor pairs is made easy with the aid of in-built test access ports in the connector.